July 2009

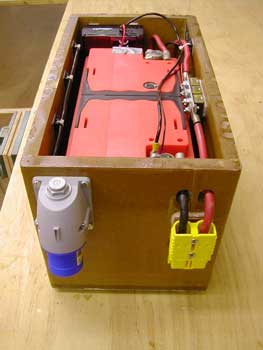

Every winch needs a power supply so that became the next project. This power supply had to contain a large battery, a charger and a master switch.

The box I made from MDF which was cut to size at my local

B&Q merchant. Having glued this together I

coated it in epoxy, inside and out, and reinforced the external edges with glassfibre tape.

The holes are for cooling the charger should it be required.

The box I made from MDF which was cut to size at my local

B&Q merchant. Having glued this together I

coated it in epoxy, inside and out, and reinforced the external edges with glassfibre tape.

The holes are for cooling the charger should it be required.

The charger, supplied by

the Alternative Energy Store

and the Master switch by

Auto Rambo Tools

are positioned at one end of the box. The Master switch has additional switching contacts

so that the solar charger I want to use for keeping the battery topped up is disconnected when

the winch is drawing current from the battery.

The charger, supplied by

the Alternative Energy Store

and the Master switch by

Auto Rambo Tools

are positioned at one end of the box. The Master switch has additional switching contacts

so that the solar charger I want to use for keeping the battery topped up is disconnected when

the winch is drawing current from the battery.

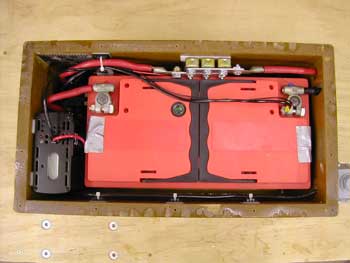

Here is the finished assembly waiting for the lid and a coat of paint. The

wiring and ancillary components came from

Auto Electric Supplies

and

Torberry.

Here is the finished assembly waiting for the lid and a coat of paint. The

wiring and ancillary components came from

Auto Electric Supplies

and

Torberry.

Since posting this months blog I've received a few comments about using MDF for this battery box.

First off, this is not for the boat so don't panic. I chose MDF for a quick easy to work solution

for a land based project.

With hindsight some 3/4" ply would have been a more durable solution but that was not to be. Oh, to have more time

to do a better job. But if I had more time I'd be driving my slipper launch by now...

And finally the winch is installed and operational.

And finally the winch is installed and operational.

And amongst all this diversionary work I managed to fillet the keel to hull joint. Not as good a fillet as I would have liked.

Too many voids and slump. The problem is caused by using a thin resin, ideal for wetting out glassfibre but hopeless for filleting, even

with the maximum recommended amounts of Colloidal Silica and Microfibres. Lesson learned.

And amongst all this diversionary work I managed to fillet the keel to hull joint. Not as good a fillet as I would have liked.

Too many voids and slump. The problem is caused by using a thin resin, ideal for wetting out glassfibre but hopeless for filleting, even

with the maximum recommended amounts of Colloidal Silica and Microfibres. Lesson learned.