January 2010

Happy New Year, to you all.

Blimey, coming back to a freezing Uk after a week of blue skies and a pleasant

25 degrees is quite a shock to the system. A snow bound workshop isn't too inviting either.

However, there was plenty to do...

The first task was to clear the timber off the bench, which meant putting the

Adirondack chair

together. This is my wife's project so my role was purely advisory.

Saturday afternoon saw the base assembled.

The first task was to clear the timber off the bench, which meant putting the

Adirondack chair

together. This is my wife's project so my role was purely advisory.

Saturday afternoon saw the base assembled.

Then Sunday saw the job completed. And a fine job it looks too.

Then Sunday saw the job completed. And a fine job it looks too.

All that remains if to cut the plugs flush and fit a few key coach bolts.

Not wishing for a whole weekend to pass without any boat progress, I sanded

fair the hull side.

Not wishing for a whole weekend to pass without any boat progress, I sanded

fair the hull side.

Next I cut the first two pieces of fibreglass cloth for the hull sheathing.

Fibreglass cloth is such a frustrating material to work with . You lay it out flat and it looks great.

then you pick it up to remove some debris from under it and when you put it down, it has changed

shape and no longer lies flat. And no matter how many times you brush the hull,

debris will always remain. I can't wait for this aspect of the project to be completed.

Next I cut the first two pieces of fibreglass cloth for the hull sheathing.

Fibreglass cloth is such a frustrating material to work with . You lay it out flat and it looks great.

then you pick it up to remove some debris from under it and when you put it down, it has changed

shape and no longer lies flat. And no matter how many times you brush the hull,

debris will always remain. I can't wait for this aspect of the project to be completed.

The next question is how much epoxy to mix up to wet out each piece of fabric.

I found this guide

guide

on the SP site which basically says the following quantities of resin are required when sheathing with 210g/m2 plain weave glass.

- Stage 1 - Resin for surface pre-coating as a preliminary to dry sheathing 0.16kg/m2

- Stage 2 - Wetting out glass fabric on pre-coated wood 0.2kg/m2

or wetting out fabric on bare wood 0.4kg/m2 - Stage 3 - Resin for filling coats (if peel ply not used) 0.16kg/m2

or resin for wetting out peel ply 0.07kg/m2 - Add 15% extra for resin wastage to obtain the final figure.

I cut a 250mm sq piece of fabric and mixed up 15g of resin plus hardener and poured it onto the cloth on a piece of bare plywood.

Weighing the mixing cup thereafter showed 2.5g remaining so I had used 12.5g and the fabric was fully wetted out

with not a scrap of resin to spare. Or so I thought. Then I covered half of this with peel ply which did not

require any more resin to wet it out. So I was being generous.

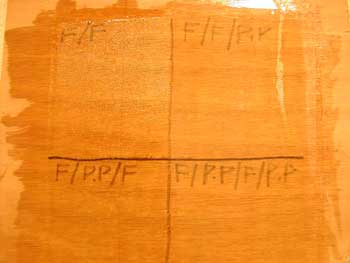

Once this had cured I added a second layer of fabric with another, this time, 13g of resin and covered half

of it with peel ply such that I had one quadrant that had not seen any peel ply, one that had seen peel ply twice

and one that only saw peel ply for the first layer and one that had only seen peel ply for the final layer.

In terms of projected resin quantity, 12.5g to 13g of resin for 250mm x 250mm

(62500mm2) of fabric which equates to 200g of epoxy per 1m2 of 127gsm fabric which is

exactly half what is says in the SP guide for a fabric weight almost twice as heavy. So not an unreasonable result.

In terms of projected resin quantity, 12.5g to 13g of resin for 250mm x 250mm

(62500mm2) of fabric which equates to 200g of epoxy per 1m2 of 127gsm fabric which is

exactly half what is says in the SP guide for a fabric weight almost twice as heavy. So not an unreasonable result.

Having removed the peel ply and compared the finish of the 4 layups I can't see any benefit for covering

the first layer with peel ply. So I'll only use peel ply on the final layer of fibreglass.

6 litres of Epoxy/hardener arrived this week so now all I need are a few consecutive

evenings and I can make a start.

A slightly higher ambient temperature would be nice too.