Data Logger 2

When my order for a $5 cadence display unit was cancelled by the supplier I decided to make my own.

When my order for a $5 cadence display unit was cancelled by the supplier I decided to make my own.

After my surprising success with the first

data logger

I felt confident to attempt something more adventurous with a real time display using an LCD 1602 (HD44780 with 16 digits in two rows).

Here it is temporarily fitted to the bike with tape.

For those who haven't read

data logger

here's some background on the Arduino board and a great YouTube clip from

Fritzing.

You can download their

Fritzing Software

for circuit design including the Arduino board.

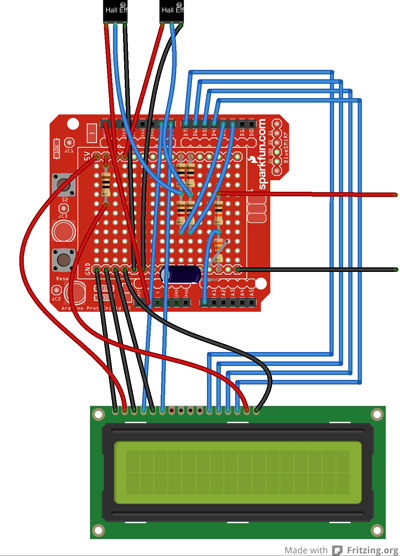

Here's my attempt at a pictorial representation of the Logger and Display using Fritzing.

Here's my attempt at a pictorial representation of the Logger and Display using Fritzing.

It took a while to locate a concise guide to writing Arduino code as most books also include in depth hardware explanations as well.

The

Arduino Programming Notebook

is a perfect code summary.

Component suppliers were:

- Arduino Uno from Phenoptix or ProtoPic or Amazon

- SD shield from Phenoptix or ProtoPic

- Electrical components from Technobots

Here's my code.

/*

This sketch is to log and display parameters to SD card and an LCD 1602

The display is HD44780 compatible and uses the LiquidCrystal.h library

the LCD is run in 'Nibble' mode using D4,D5,D6,D7 & D4 for Enable and D9 for RS

Cadence/Speed is measured using a Cherry MP101401 Hall effect sensor on an interrupt line

Tilt and Compass heading are comms through Ic2 (two wire)

The SD card is Adafruit and comms through SPI

D0 (Rx)

D1 (Tx)

D2 Cadence (interrupt)

D3 Speed (interrupt)

D4 Data7 = LCD14

D5 Data6 = LCD13

D6 Data5 = LCD12

D7 Data4 = LCD11

D8 Enable = LCD6

D9 RS = LCD4

D10 CS - SD Card SPI

D11 MOSI - SD Card SPI

D12 MISO - SD Card SPI

D13 SCK - SD Card SPI

A0 Battery voltage (5v ref)

A1

A2

A3

A4 SDA - Inclination & Heading

A5 SCL - Inclination & Heading

Full house on digital i/o

three spare analogue lines

V1.03

02/07/2013

*/

#include ‹LiquidCrystal.h›

#include ‹SPI.h›

#include ‹SD.h›

#include "RTClib.h"

#include ‹Wire.h›

// initialize the library with the numbers of the lcd interface pins

LiquidCrystal lcd(9, 8, 7, 6, 5, 4);

#define LOG_INTERVAL 100 // define logging rate at 10Hz

#define SYNC_INTERVAL 1000 // mills between calls to flush() - to write data to the card 1Hz

uint32_t syncTime = 0; // time of last sync()

#define numReadings 10 //number of readings to average vBatt over

// define the Analogue inputs; Battery voltage, cadence and bike speed

#define vBattpin 0 // analog 0

#define cadenceInterrupt 0 // Interrupt 0 on D2

#define cadencePin 2 // Interrupt line to D2 = interrupt 0

#define vBikeInterrupt 1 // Interrupt 1 0n D3

#define vBikePin 3 // Interrupt line to D3 = interrupt 1

// define constants

const int chipSelect = 10; // CS pin required by SD library

// define variables

unsigned int frac; // fractional content of vBatt for lcd display purposes

// initialise the variables for the vBatt averaging routine

float readingsToAverage[numReadings]; // the array to contain 10 vBatt readings

float total = 0; // the running total of the array of vBatt readings

int index = 0; // the averaging routine index (counts from 0 to 9)

int count = 0; // the number of valid values in the array before it reaches 10

// define volatiles used in the ISR

float start; // Time since last ISR updated in ISR for rCadence

float start2; // Time since last ISR updated in ISR for vBike

float elapsed; // Current time in ISR calculated from millis() - start(2)

float rCadence; // Cadence rpm

float rWheelSpeed; // Front wheel speed in rpm

float vBike; // Bike speed in kph

RTC_DS1307 RTC; // define the real time clock object.

// the logging file

File logfile;

void setup()

{

// set the input pins

pinMode(vBattpin, INPUT); // vBattery analogue input

pinMode(cadencePin, INPUT); // Cadence interrupt pin

pinMode(vBikePin, INPUT); // vBike interrupt pin

// set the output pins

pinMode(10, OUTPUT); // for SD shield make sure that the default chip select pin is set to Output

// use the lcd display to verify the setup process

lcd.begin(16,2);

lcd.setCursor(0,0);

lcd.print("Initialising SDc");

delay(500);

// see if the card is present and can be initialized:

if (!SD.begin(chipSelect))

{

lcd.setCursor(0,1);

lcd.print("Card failed");

while(1); // stop here indefinitely

}

lcd.setCursor(0,1);

lcd.print("Card Init Ok");

delay(1000);

// create a new file

char filename[] = "LOGGER00.CSV";

for (uint8_t i = 0; i < 100; i++)

{

filename[6] = i/10 + '0';

filename[7] = i%10 + '0';

if (! SD.exists(filename))

{

// only open a new file if it doesn't exist

logfile = SD.open(filename, FILE_WRITE);

break; // leave the loop

}

}

if (! logfile)

{

lcd.setCursor(0,1);

lcd.print("C'not create fn");

}

lcd.clear();

lcd.setCursor(0,0);

lcd.print("Logging to");

delay(500);

lcd.setCursor(0,1);

lcd.print(filename);

delay(1000);

// connect to Real Time Clock

Wire.begin();

lcd.clear();

lcd.setCursor(0,0);

lcd.print("RTC Setup");

if (!RTC.begin())

{

lcd.setCursor(0,1);

lcd.print("RTC Failed");

}

delay(1000);

lcd.setCursor(0,1);

lcd.print("RTC OK");

delay(1000);

// setup display

lcd.clear();

lcd.setCursor(0,0);

lcd.print("vBat");

lcd.setCursor(7,0);

lcd.print(".");

lcd.setCursor(9,0);

lcd.print("v");

lcd.setCursor(13,0);

lcd.print(":");

lcd.setCursor(0,1);

lcd.print("rCad");

lcd.setCursor(7,1);

lcd.print("rpm");

lcd.setCursor(13,1);

lcd.print("kph");

// write header to csv on SD

logfile.println("millis,date,time,vBatt,vBattAverage,rCadence,rWheelSpeed,vBike");

// initialise all averaging routine readings to zero

for (int thisReading = 0; thisReading < numReadings; thisReading++)

readingsToAverage[thisReading] = 0;

}

void cadenceCalc() // ISR routine for cadence calculation

{

elapsed = millis() - start; // time since last ISR

start = millis(); // update to current time

rCadence = 60000 / elapsed; // cadence in rpm

}

void vBikeCalc() // ISR routine for bike speed calculation based on front wheel rpm

{

elapsed = millis() - start2; // time since last ISR

start2 = millis(); // update to current time

rWheelSpeed = 60000 / elapsed; // Front wheel rpm

vBike = rWheelSpeed * 0.13194678; // Convert wheel rpm to rev/hour and multiply by wheel circumference (700c) 60 x 0.0022

}

void loop()

{

// setup the ISR

attachInterrupt(cadenceInterrupt,cadenceCalc,FALLING);

attachInterrupt(vBikeInterrupt,vBikeCalc,FALLING);

DateTime now = RTC.now();

// delay for the amount of time we want between readings

delay((LOG_INTERVAL -1) - (millis() % LOG_INTERVAL));

// vBattpin is referenced to 5v

// The voltage divider uses 10k/3k3 resistors

// The multiplier is (5/1024)*(13,300/3,300) = 0.0197

float vBatt = analogRead(vBattpin) * 0.0197;

// averaging script

total-= readingsToAverage[index]; //subtract the last reading

readingsToAverage[index] = vBatt; // read from the sensor

total += readingsToAverage[index]; // add the reading to the total

index ++; // increment index

index = index % numReadings; // reset index if = 10 (array 0 to 9)

// could use "if (index == numReadings) index = 0"

if (count < numReadings) count++; //count is current number of valid samples in the array

float vBattAverage = total / count;

// write data to lcd

//vBatt

frac = (vBatt - int(vBatt)) * 10; // frac contains the first decimal place of vBatt

lcd.setCursor(5,0);

lcd.print(int(vBattAverage)); // display integer part

lcd.setCursor(8,0);

lcd.print(frac, DEC); // display first decimal place

// time

lcd.setCursor(11,0);

lcd.print(now.hour(), DEC); // display hour

lcd.setCursor(14,0);

lcd.print(now.minute()); // display minutes

// rCadence

lcd.setCursor(5,1);

lcd.print(int(rCadence)); // display cadence

// vBike

lcd.setCursor(11,1);

lcd.print(int(vBike)); // display bike speed

detachInterrupt(cadenceInterrupt); // detach interrupt while writing to SD card

detachInterrupt(vBikeInterrupt); // detach interrupt while writing to SD card

// write time and data to SD card

uint32_t m = millis(); // log milliseconds since starting

logfile.print(m);

// write the time and data

logfile.print(", ");

logfile.print(now.year(), DEC);

logfile.print("/");

logfile.print(now.month(), DEC);

logfile.print("/");

logfile.print(now.day(), DEC);

logfile.print(",");

logfile.print(now.hour(), DEC);

logfile.print(":");

logfile.print(now.minute(), DEC);

logfile.print(":");

logfile.print(now.second(), DEC);

logfile.print(", ");

logfile.print(vBatt);

logfile.print(", ");

logfile.print(vBattAverage);

logfile.print(", ");

logfile.print(rCadence);

logfile.print(", ");

logfile.print(rWheelSpeed);

logfile.print(", ");

logfile.print(vBike);

logfile.println();

//Now we write data to the card & update FAT

if ((millis() - syncTime) < SYNC_INTERVAL)

{

return;

}

else

{

syncTime = millis();

logfile.flush();

}

}

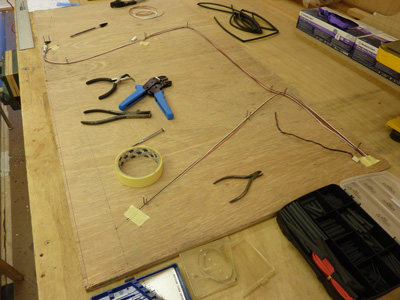

Here's the loom being assembled using 24swg wire, red and black for power and ground and white for signal and

the connectors are

JST-JWPF from RS.

Here's the loom being assembled using 24swg wire, red and black for power and ground and white for signal and

the connectors are

JST-JWPF from RS.

Here's the loom finished and ready for installation on the bike.

Here's the loom finished and ready for installation on the bike.

Here's the cadence sensor. I've used a

hall effect sensor from RS and a couple of 8mm diameter

neodymium magnets,

which you can just see on the end of the pedal spindle. The hall effect sensor is held in place with hot melt glue on clear tape.

Here's the cadence sensor. I've used a

hall effect sensor from RS and a couple of 8mm diameter

neodymium magnets,

which you can just see on the end of the pedal spindle. The hall effect sensor is held in place with hot melt glue on clear tape.

Here's the speed sensor attached to the inside of the front forks with another trigger magnet bonded onto the wheel rim.

Here's the speed sensor attached to the inside of the front forks with another trigger magnet bonded onto the wheel rim.

Here's the complete bike ready for it's first test run with the new logger.

Here's the complete bike ready for it's first test run with the new logger.

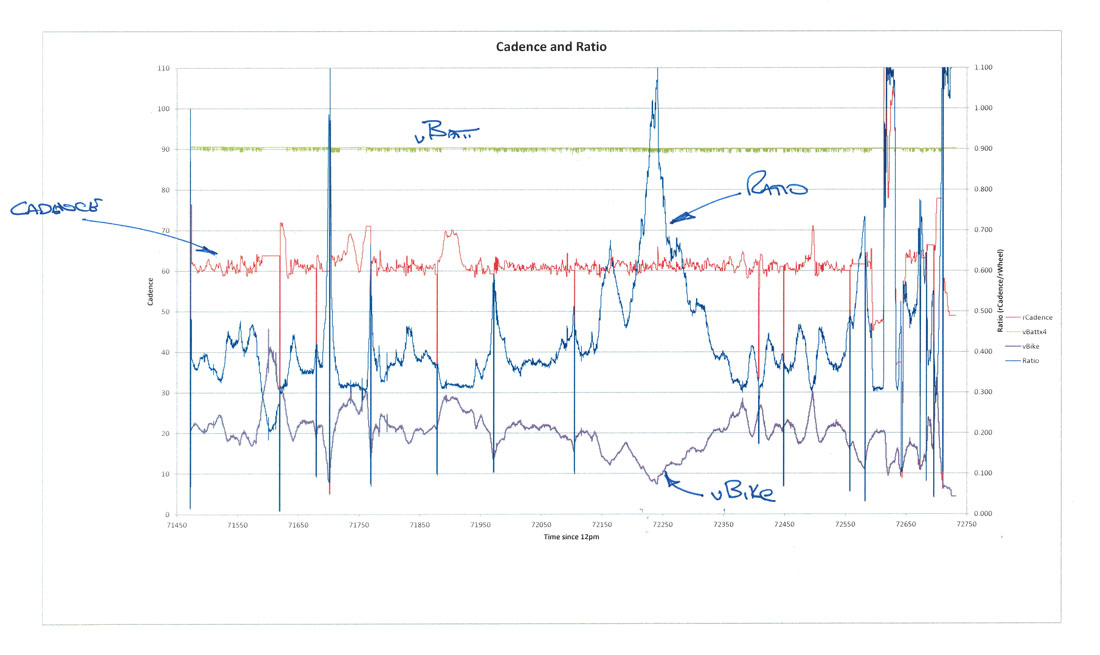

Here's some typical data taken from the logger showing a cadence target ≈ 62rpm (red) with speed (purple) and ratio (blue) which in this case is simply cadence divided by wheel speed.

The green trace is battery voltage and noise on this signal indicates shift activity in the Nuvinci hub. When the Nuvinci runs out of authority,

because it is in the highest or lowest gear ratio, the cadence changes from the demanded value and there is no shift activity influence seen on the battery voltage.

This can be seen in a few cases on this trace when going downhill as I have geared the bike for climbing and input low torque.

Where the cadence trace appears to drop out it is because I have stopped pedaling and the time period between interrupts is large.